I’ve been restoring my 1940s Scully record lathe for nine or ten years now, and it’s only been very recently that I have got all the internal gear workings together. It’s still not up and running, but it’s REAL close. But when I started testing the functionality of the lathe, I made a terrifying discovery!

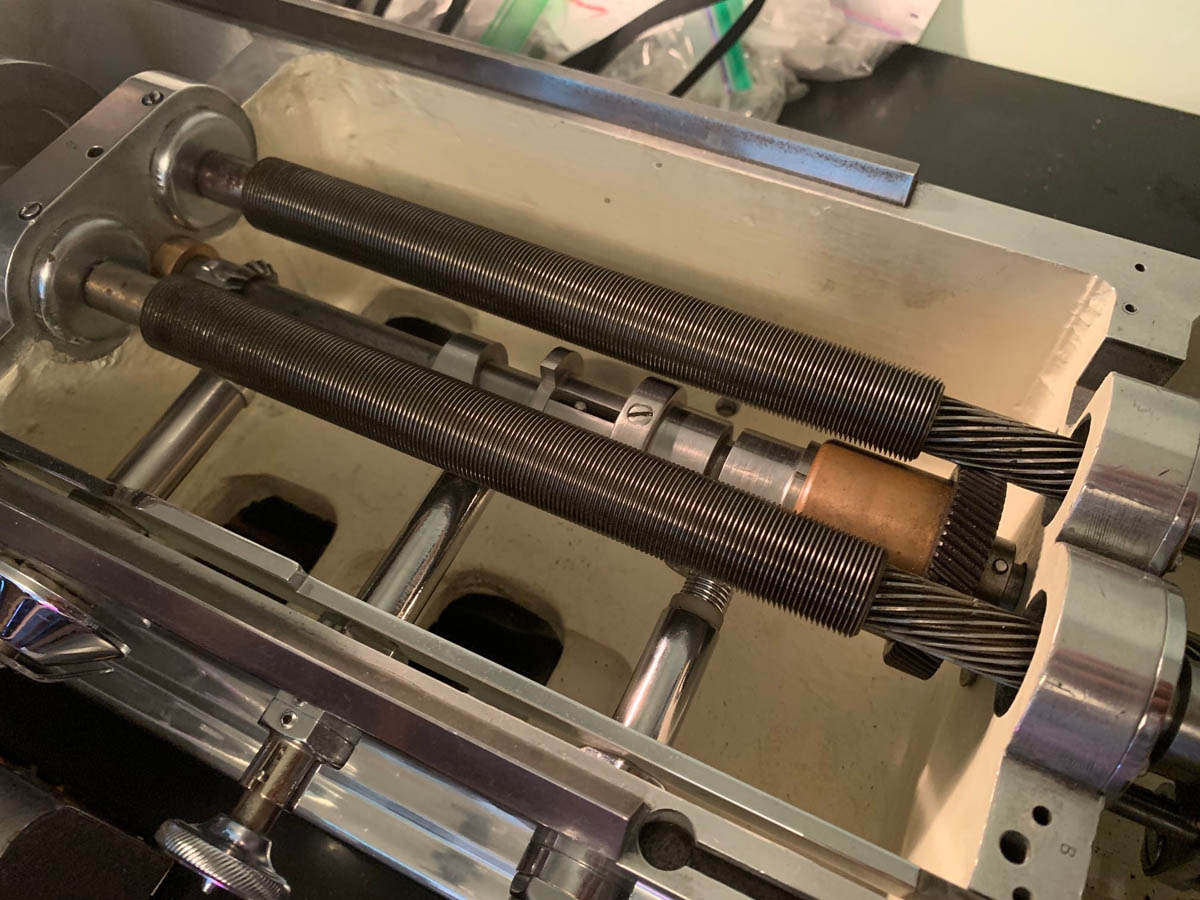

The way these machines were built back in the 1930s and 1940s, there were two “lead screws” that slowly turned from a belt drive with the giant drive motor underneath. These lead screws locked into a “half nut,” which carried the rolling carriage that holds the cutting head. This slow rotation of the lead screws and the rolling carriage allows a record to be cut, making very slow spirals as it goes.

The reason that Scully lathes had two lead screws is because back in the day, many radio transcription records were cut so they would play “inside out,” starting the groove from the inside of the record near the center hole, and playing out to the edge. So, one lead screw had threads that would cut an “inside out” or “backward” record, and one lead screw would cut “outside in,” or like a normal record.

I bought my lathe completely disassembled in a bunch of boxes, and as I’ve been slowly putting it together, I never had it “all together” until recently. That’s when I discovered, for some reason, my lathe has TWO “inside out” or “backward” lead screws! I even had a spare lead screw, and it was inside out as well! So, this machine must have been used to cut radio transcription records and was never set up to cut “normal” outside-in records. What a bummer to discover this so far along in the restoration process!

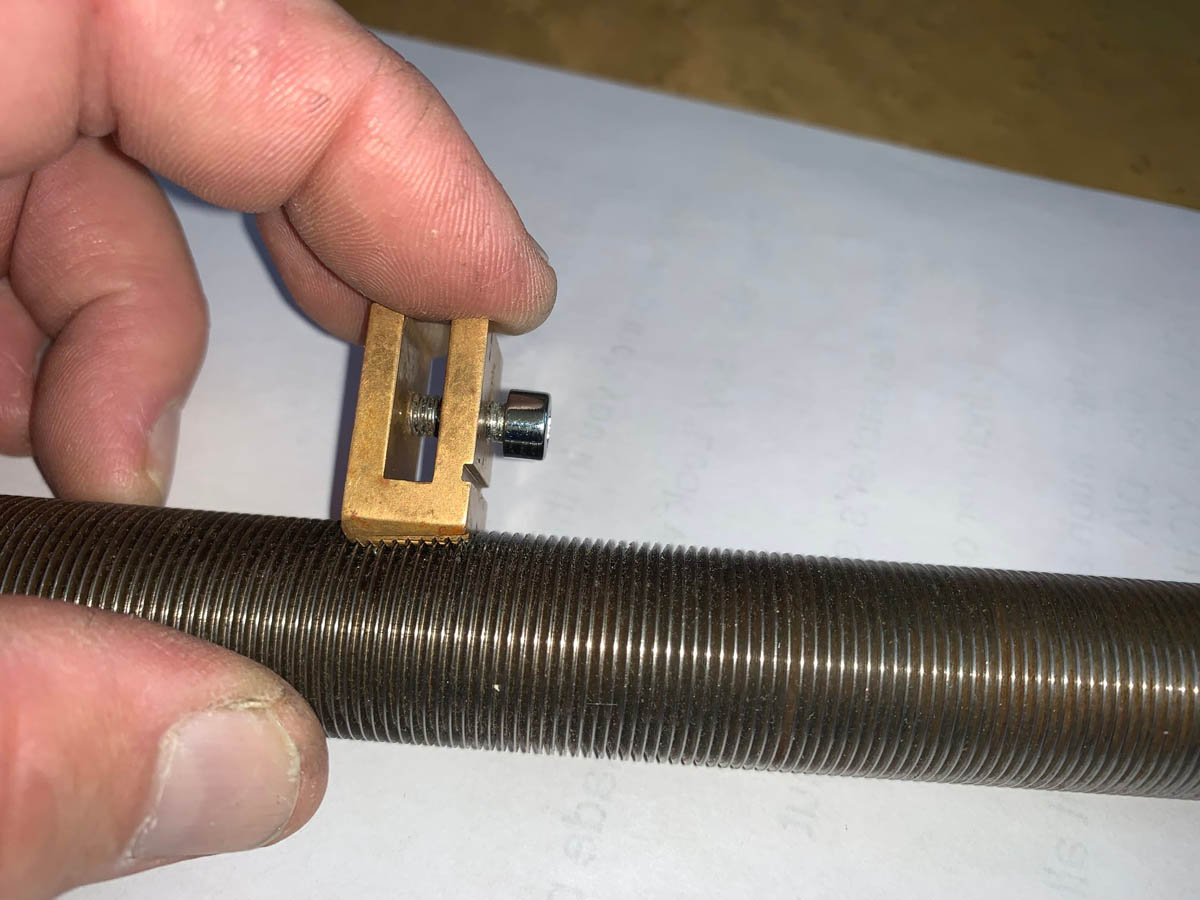

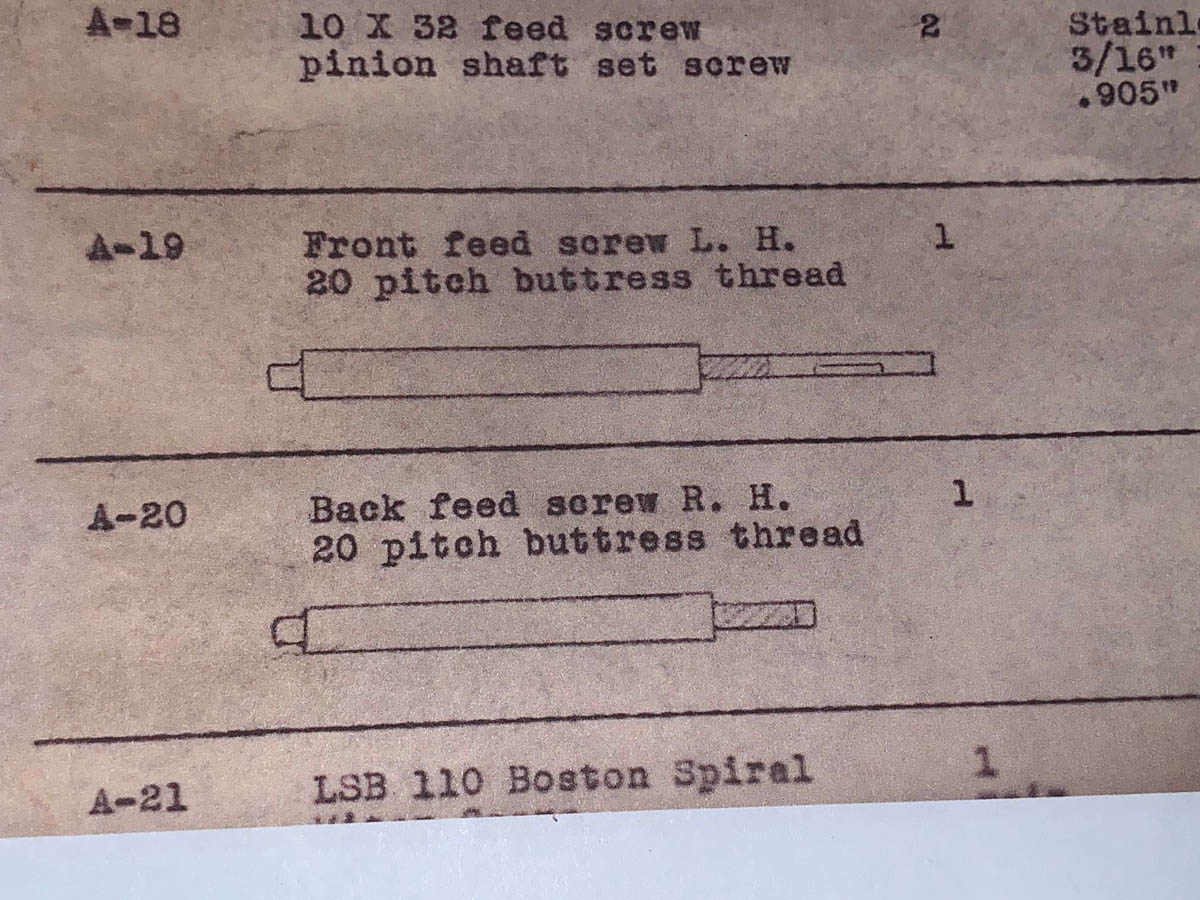

It’s not as simple as just turning the drive unit in reverse, or cutting and welding the existing lead screw backward, or anything like that. The lead screws are cut with a one-way “buttress thread,” so modifying the one I have simply won’t work.

So, I threw out lines to the dozen or so people I know who own Scully lathes to see if anybody might have a spare outside-in lead screw. (There are maybe thirty-five or forty of these machines left in the world, out of six hundred or so that were made back in the day). Nobody had one they would sell. Scully lathe parts are rare to nonexistent.

There are a couple of lathe experts here in LA—they are “the guys” for this stuff, and they have one spare lead screw, but because they are sort of the last-gasp world resource for this stuff, they won’t sell it to me. They did offer to take their lead screw to the local lathe machinist guy to have a replica made. This is a valid option, BUT the lathe guys tell me they won’t be taking the lead screw project to the machinist until next year sometime because they are waiting on several other machining projects from the guy. Then, the machinist usually takes eight to twelve months to finish a job, because he’s very good and he’s always busy. So, this lead-screw-replicating project looks to delay my lathe restoration by another year and a half or two years. Ugh!

So, this is my question for the hive mind out here, and especially the old-timers who really know their stuff: I’d like to have a proper lead screw and half-nut made up. I know it won’t be cheap, but that’s what I’m looking at and there’s no way around it.

Here’s what I need:

1. Lead screw with 20-pitch “left hand” buttress thread and a secondary spiral thread on the end where the drive shaft gear attaches to the lead screw.

2. Matching “half nut” with reverse buttress threads; this half nut is attached to the rolling carriage and connects with the lead screw when spiral-drive operation is engaged.

If any of you machinist guys have any good recommendations, I’m all ears! Let me know. This has been a really discouraging and frustrating development in the Scully lathe restoration, I could really use some good news that doesn’t leave me waiting two years for the part I need!